Introduction

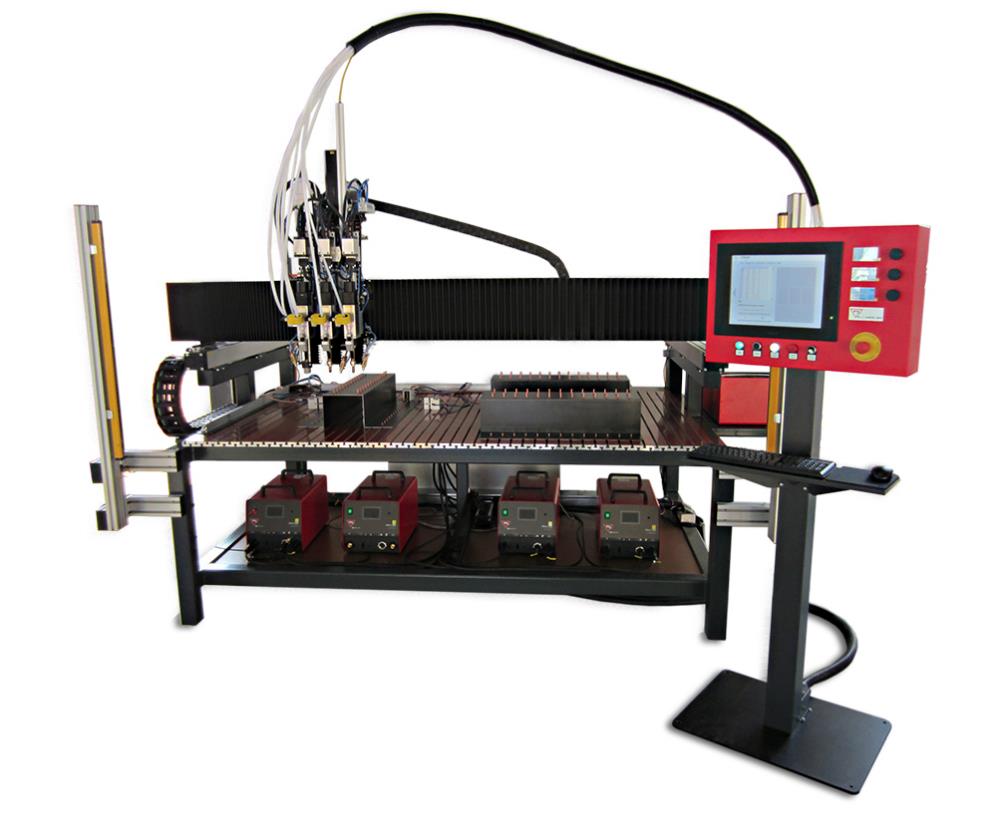

CNC/Full automatic stud welding system Series T

The fully automatic series T stud welding machines warrant a maximum of precision and reliability through their robust construction and the use of high-value components. The available working areas as well as numerous possible option enable the customer-specific design of the machines.

-

working area X/Y: 1000 x 700 mm, 1250 x 850 mm or 1500 x 1000 mm (Other dimensions upon request as special production.)

The entire working area can be reached by each welding head. -

welding range

stud diameter 3-8 mm, stud length 6-50 mm (Other diameters and lengths as well as special welding elements upon request as special production.) -

max. number of stud welding heads: 4

(The machine concept is designed for four working stations. If a milling unit is used at the most three stud welding heads can be mounted.) -

max. operating speed of the X-/Y-axis: 30 m/min

-

positioning accuracy of the welded studs: +/- 0,2 mm

-

Fast and easy programming by operating software i1stud.

i1stud enables - besides programming directly on the machine - entering the welding coordinates on an external PC. Thus idle times by programming on the machine can be avoided.

optional: operating software i3stud (inkl. DXF data converter) with operating terminal with industrial panel PC

(DXF data import: The customer-specific DXF-data are automatically converted and transfered to the controller. Visualization of the program sequence.) -

ample program memory

-

mobile operating panel

-

very easy operation

-

welding parameter monitoring and documentation (by stud welding units PRO-D/PRO-C)

- recording of welding current, welding time and arc voltage for each weld

- recording of stud travel (lift, piston runtime, immersion depth) for each weld [only when an automatic welding head with travel measuring system is used]

- comparison of the recorded welding parameters (actual values) to the parameters of a reference weld (set values) (tolerances adjustable)

- in case of variances to the reference weld a warning is displayed or the unit is locked for further welds until the release by the operator (functionality can be switched off)

- storage of the last ten welding parameter sets

- optional (also retrofitable): welding parameter memory for the storage of 24500 welding parameter sets (storage with date and time) with USB-interface for data transmission (welding parameter sets) to a PC

- optional (also retrofitable): PRO-xDataLog

The software PRO-xDataLog enables - besides reading out the welding parameter memory - the real-time transmission (Live Logging) of the welding parameter sets recorded by the stud welding unit to a PC that is connected to the stud welding unit. Immediately after each weld the welding parameter set (with date and time) that is recorded by the unit is written into a file on the connected PC. There the data can be analyzed (e.g. by MS Excel) and stored. -

automatic stud feeding

-

very good accessibility of the machine

-

flexible positioning of the pneumatic clamps on the machine table

-

short set-up and retooling times

-

quick change system for welding heads

-

free zero points (zero point shift)

-

re-weld function with program continuation

-

optional protection devices:

- housing with door (design as sliding, folding or lift door (if required also pneumatically)) or light curtain

- light curtain

- safety fence -

high processing speed due to dynamic servo motors

-

premium axes with high-precision guides and threaded spindle or belt drive warrant a maximum of precision and reliability

-

inside slide mountings with cover bands avoid damages to the drive caused by welding spatters, smoke and dust

-

very robust and warp resistant welded steel machine frame

-

machine table made from aluminium T-grooved plates with laminated fabric plates for electrical insulation and as wear protection

-

stop bars (150 mm behind the X- and the Y-zero point) facilitate the setting up of the variable stop positions

-

pneumatic working lift/welding head 80 mm (mechanic adjusting range through precision crank handle 40 mm)

-

The machines are suitable for all stud welding methods.

The following stud welding units and automatic stud welding heads can be used:

PRO-C 1000/1500 = stud welding units for capacitor discharge stud welding (contact and gap method)

PRO-D 1200/1600 = stud welding units for drawn arc and short cycle stud welding

KHA-200F with integrated travel measuring system = automatic stud welding head for capacitor discharge (gap and contact method), drawn arc and short cycle stud welding

KKA-200F = automatic stud welding head for capacitor discharge stud welding (contact method) -

connection values

electrical (mains supply, mains fuse external): 400 V/50 Hz, 16A

pneumatical: ≥ 6 bar, unoiled, dry, clean

OPTIONS:

-

servo motor-driven Z-axis 250 mm for the exact and fast positioning on different levels

-

fluid spraying device for targeted wetting of the welding point before welding for each welding head

-

milling unit with exhaust device for targeted removal of problematic surface layers at the welding point

-

pneumatic single stud feeding, manual stud insertion (e.g. for feeding special studs (special geometries, overlong studs))

-

stud switch for feeding studs with the same diameter but different lengths into one welding head

-

pneumatic mass clamps standard

-

pneumatic mass clamps aperture angle 90°

-

mechanic mass clamps mounted on welding head

-

pneumatic mass clamps mounted on welding head

-

workpiece downholder for each welding head

-

shielding gas module for each welding head

More Products